Solar Sludge Drying Model

Also the automation degree of sewage sludge feeding and removal is variable.

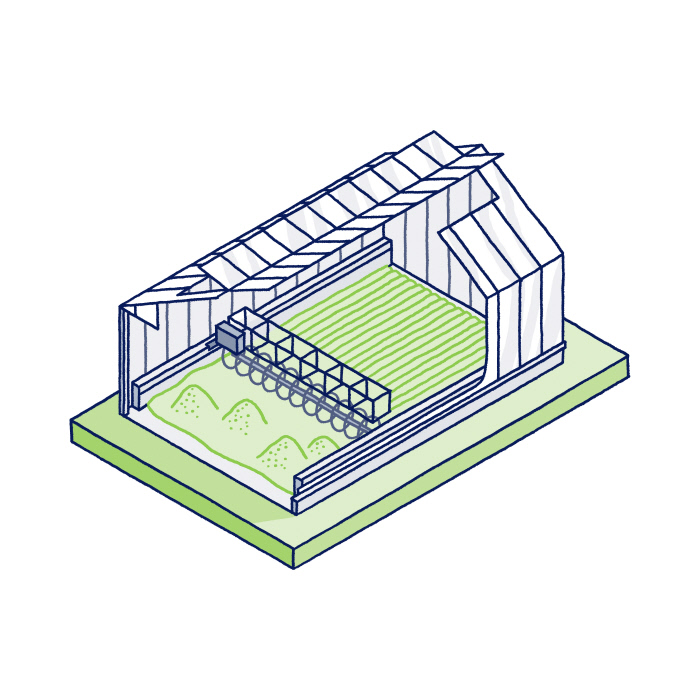

Solar sludge drying model. Solar sludge drying excels in fulfilling key economic and environmental goals. Total areas occupied by gsds and solar panels at wwtps were equivalent to 0 1 for wwtp 37 to 71 for wwtp 14 of the existing wwtp areas. Ventilation with dry air from the outside. Dewatered sludge and drying sludge are mixed and shaped into windrows by the soliamix windrow turner.

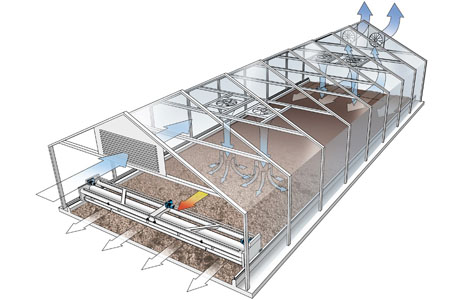

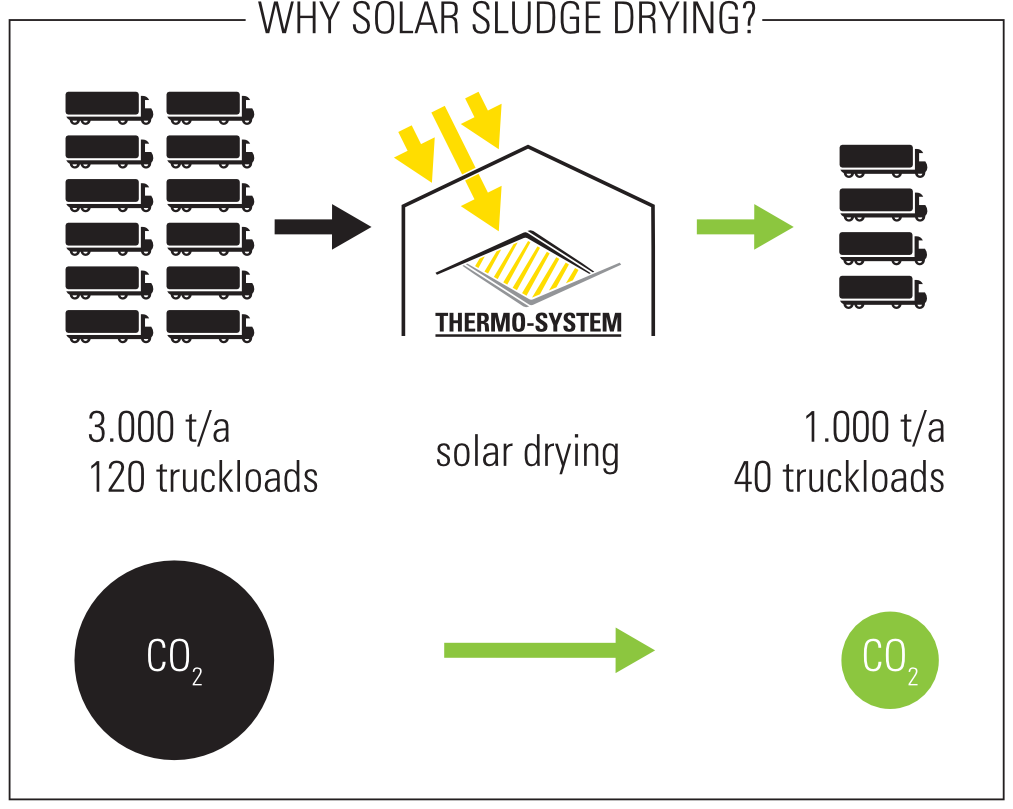

According to a multiplicative model for sludge solar drying developed by seginer and bux 15 a corresponding drying rate between 6 3 and 9 3 kg h 2 o m 2 á day can be calculated based on the. Solar energy is used to extract water from sewage sludge a simple and cheap process that not only reduces the sludge considerably in terms of volume but also saves truck mileage and c0 2 emissions. The combined sludge turning and transporting system is at the heart of the drying plant. For the largest plant production rate of 25 900 kg sludge hr with ds i i of 22 land requirement for the drying system was 56 of the existing area.

The aim of this study is the modelling with a two scale approach of the. For wwtp 2 production rate of 13 223 kg sludge hr with ds i i of 26 requirement decreased to 18. The mole tills the sludge bed bringing the moist sludge to the drying surface. A special sludge turning system performs both spreading and turning of the sludge as well as its transport from one side to the other.

The sludge is transported. The solar sludge drying systems can be erected on a variety of flat or inclined surfaces in a range of climates and can be adapted to retrofit existing drying beds. Sludge can be dried in batches using a semi continuous process by means of a fully. As the sludge dries the mole granulizes it into a uniform consistent pelletized end product.

Windrow operation and regular addition of fresh sludge maximize bio drying and promote easy storage of sludge on a 6 months to 1 year cycle in the greenhouse. The huber solar regenerative sludge dryer srt is able to meet the most different specific customer requirements whether as a pure solar dryer or all year round dryer operated with additional heat. Three processes are available. Huber solar active dryer srt.

The limits of mechanical sludge drying sometimes create the need for thermal drying by water evaporation. The basic principle of the system is drying of sewage sludge in a glasshouse using the incident solar radiation. Drying sludge for optimal recovery. Solar radiation along with bio drying.

Disposal of that sludge which contain 20 dry solids is very difficult without drying process.